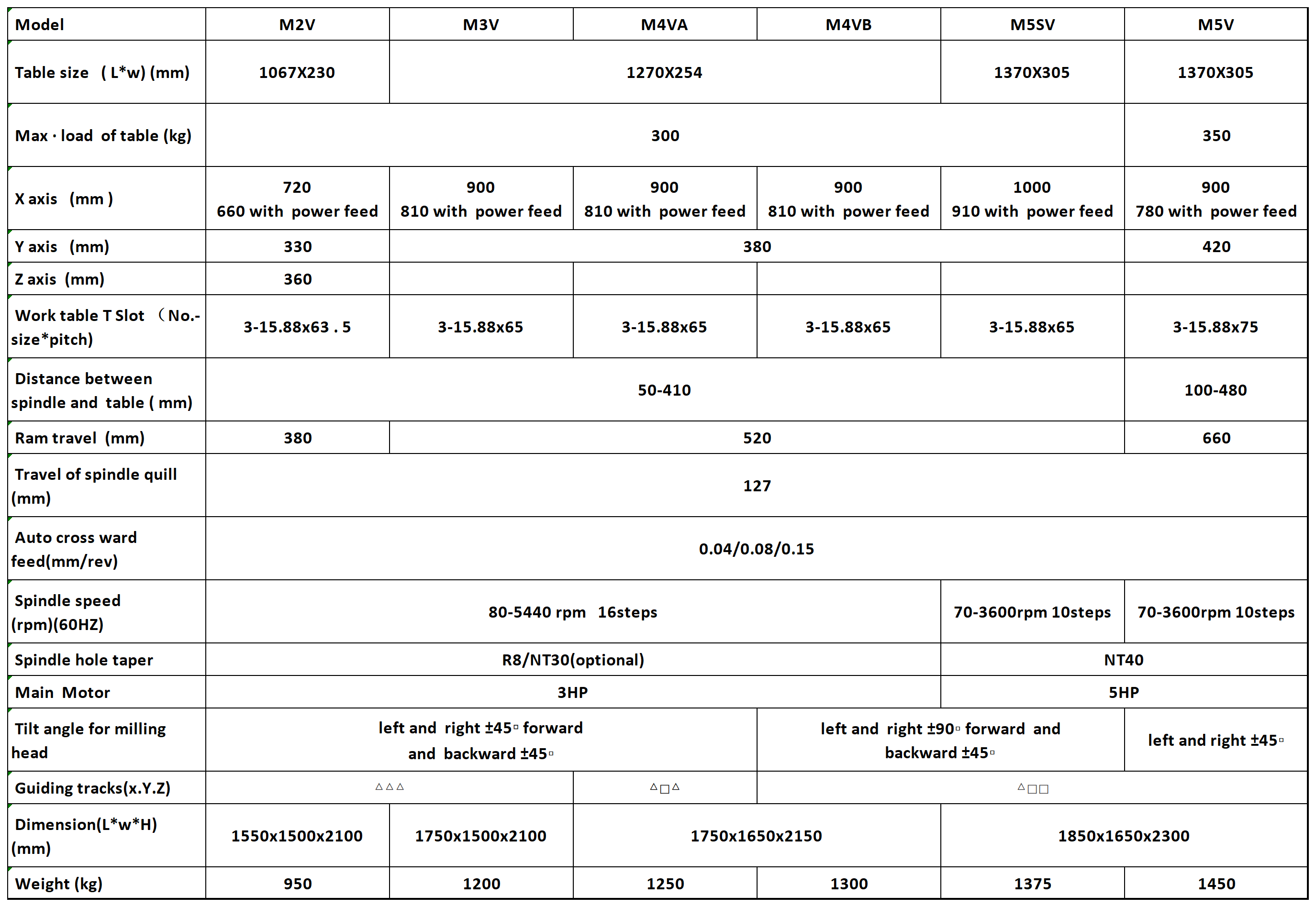

Turret Milling Machine

Features

1. The coil is made of copper wire with a capacity of 3 horsepower.

2. The gear is made from 20CrMnTi material, with a carburization depth of 0.5-0.8mm, and has undergone high-frequency treatment resulting in a hardness of HRC 52-56.

3. The automatic feeding has been modified to use three bearings for smoother operation, while the copper turbine is made from phosphorus bronze, known for its excellent wear resistance.

4. The spindle housing is a cast metal component made through a resin sand casting process, utilizing high-strength HT250 with low stress for shock resistance and wear durability.

5. The spindle is made from 40Cr steel and has been tempering-treated to a hardness of HRC 52-56. A Japanese torque wrench is used to ensure the accuracy of the spindle.

6. The mesh structure provides good rigidity, is lightweight, and has minimal movement accuracy error.

7. The double dovetail guideways are coated on all four sides, resulting in a lifespan twice that of traditional models.

8. The dual-direction eight supporting screws (8 for the number 5 machine) provide locking strength double that of traditional models.

9. The display of the spindle uses stable single-chip performance, with a Taiwan Mean Well power supply, Korean guide rails, German positioners, and an American original potentiometer with accurate gradation.

10. The expandable locking disc maintains rigidity under dual-directional forces without deformation.

11. The double-wall design enhances the rigidity of the machine body.

12. Extended support for X-axis travel of 1100mm (optional):

– Extended: X4L / X6L

– G4L / G6L

13. The oil pipe nut is securely fixed to prevent detachment.

14. The integrated lifting seat enhances load-bearing strength.

hello@ptyitech.com

+86 198 9775 4880