Bench press machine

| Specification | |||||

| Iterm | Unit | REC-PZ-5KN-SF | REC-MZ-5KN-SF | REC-MZ-10KN-SF | REC-MZ-20KN-SF |

| Pressure accuracy level | 1 | 1 | 1 | 1 | |

| Maximum pressure | KN | 5 | 5 | 10 | 20 |

| Pressure range | KN | 0.05-5 | 0.05-5 | 0.1-10 | 0.2-20 |

| Resolution | N | 0.32 | 0.32 | 0.64 | 0.76 |

| Sampling times | times/sec | 800 | 1200 | 1200 | 1200 |

| Maximum stroke | mm | 100 | 200 | 200 | 200 |

| Enclosed height | mm | 200 | 300 | 300 | 300 |

| Throat depth(Distance from spindle to column ) | mm | 120 | 120 | 120 | 120 |

| Displacement resolution | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| Positioning accuracy | mm | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Pressing speed | mm/s | 0.01-35 | 0.01-35 | 0.01-35 | 0.01-35 |

| No-load speed | mm/s | 100 | 100 | 125 | 125 |

| Minimum speed that can be set | mm/s | 0.01 | 0.01 | 0.01 | 0.01 |

| Pressure holding time | s | 0.1-150 | 0.1-150 | 0.1-150 | 0.1-150 |

| The minimum pressure holding time can be set | s | 0.1 | 0.1 | 0.1 | 0.1 |

| Equipment power | W | 500 | 500 | 750 | 2kw |

| Power supply voltage | V | AC220 | AC220 | AC220 | AC220 |

| Dimensions | mm | 533*495*1069 | 543*516*1360 | 540*560*1550 | 540*560*1550 |

| Weight | kg | 100 | 200 | 180 | 180 |

Product advantages

1.High equipment precision, displacement accuracy ±0.01mm, load accuracy ±1%.

2.Independently developed software, easy to maintain. (most of the market uses PLC control. Our company uses FPGA as the main chip and industrial computer as the terminal, providing unlimited possibilities for data storage and analysis.)

3.Various pressing modes, load control and position control.

4.Real-time recording of pressing data and ability to save and analyze data. (most of the market uses PLC control and cannot save data points, but our system uses an industrial computer, making it easy to save collected points)

5.Software with alarm function, allowing setting of product load range or displacement range. If real-time data is not within the range, the device will automatically alarm.

6.The equipment is equipped with an industrial computer, and the computer interface is specially designed for pressing machines. Easy to use and convenient.

7.The equipment is equipped with a safety light curtain to ensure the safety of operators.

8.Achieve precise displacement and pressure control without the need for hard limit and precision fixtures.

9.Online assembly quality management technology to remove defective products in real-time.

10.Optimize the pressing process based on specific product requirements.

11.Specific, complete, and accurate recording and analysis functions of the pressing operation. (The curve has functions such as zooming and traversing)

12.Automatic compensation function to achieve pressing control that hydraulic presses cannot achieve.

13.Can achieve multiple uses, flexible wiring, and remote device management.

14.Multiple data formats can be exported, and data can be easily imported into SPC and other data analysis systems.

15.Self-diagnostic function: When the device has a fault, the electronic press can display error messages and suggest solutions, making it easy to quickly identify and solve problems.

16.Multi-function I/O communication interface: Through this interface, communication with external devices is possible, facilitating full automation integration.

17.The software supports multiple permission settings.

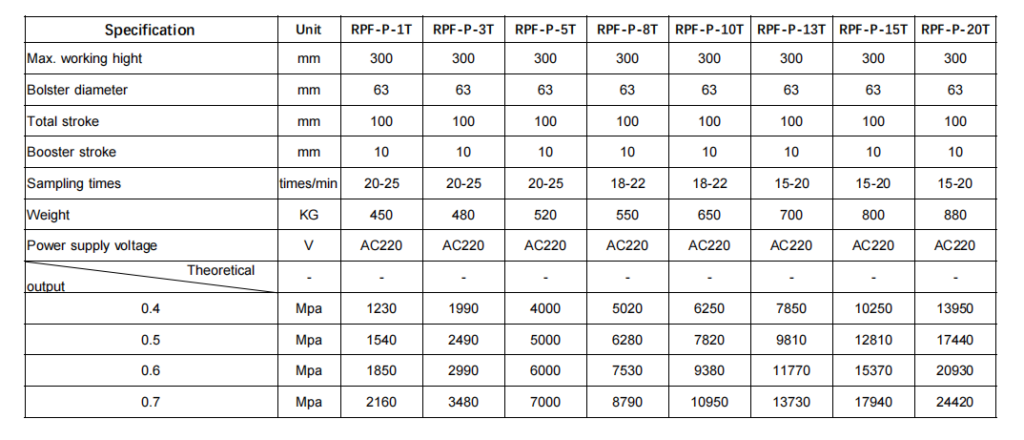

Pneumatic Hydraulic Equipment

Product Features of Pneumatic Hydraulic Equipment

High efficiency and easy operation, reducing operator fatigue

The design of the press is easy to use for part compression, punching, bending, and printing

Simple structure, requiring minimal maintenance

Fast and smooth operation

The design of the column base and * structure facilitates long-term operation

Lightweight and easy to move

Equipped with safety devices to provide comprehensive safety protection during operation

Vertical design with button switch, can be operated with foot pedal or manual control

The cylinder shaft is equipped with a stop-rotating guide rod for more precise work.

Pneumo-hydraulic actuator

Ideal solutions for the pressing forces from 1 to 2000 kN

The booster cylinder is an integrated combination of an oil cylinder and a supercharger. It uses pure air pressure as power and uses the ratio of the piston cross-sectional area of the supercharger to convert the low pressure of the air pressure into dozens of times the oil pressure. It is supplied to the hydraulic cylinder to achieve the high-pressure output of the hydraulic cylinder.

hello@ptyitech.com

+86 198 9775 4880